DTF film is a transfer media specially designed for DTF printing, which is used to bear the patterns printed by inkjet of DTF printers, and then transferred to textile fabrics by hot pressing. High-quality DTF film is characterized by high ink-carrying capacity, clean powder shaking, easy peeling, etc. Choosing the best DTF film is crucial to your printing business because it directly affects the printing quality.

Hanrun Paper, while providing customers with high-quality products, always expects to keep close communication with customers to understand users' needs and pain points in practical applications, and discuss the enhancement and development of DTF technology together. Recently, we have received samples of other brands of hot peel DTF film sent to us by our customers. Hanrun Paper's technical experts tested them together with the latest 100μ hot peel DTF film and summarized the following points, hoping that it will be helpful for you to purchase DTF films.

In the sample test, the first thing we check is the thickness of the DTF film. Although many products on the market indicate a thickness of 100μm in the profile, but some manufacturers will cut corners in the coating operation. For example, the figure below is a sample we received from another brand, and the actual measured value is only around 89μm.

*Testing whether the thickness of the film is up to standard.

DTF films are made on a base layer of PET material coated with a release layer and an ink-absorbing layer. High-quality DTF film with backside coating realizes anti-static and anti-adhesive continuous processing. Hanrun Paper hot peel DTF film consists of 5 layers: silicone protective coating, PET base layer, hot peel coating, ink absorbing layer, and water absorbing layer. The DTF PET film coated with multiple layers is less transparent in appearance and will show a hazy frosted texture.

The base film of DTF PET film must be high-temperature resistant. There may be some films that are perfect when printed, but during the press transfer process, the base PET film curls or even melts due to the lack of high-temperature resistance. This situation can even damage the garment fabric with very bad consequences.

Coating is the key to print quality. If the coating is uneven or mixed with impurities, it will directly affect the printing effect. Therefore, it is necessary to observe whether the surface coating is even and delicate. If the coating is uneven, it will cause the ink you print is also uneven, and the final rendering of the pattern will appear noisy or mottled phenomenon. Another possible problem is a DTF transfer film with a poor-quality coating. This kind of film may look perfect at first glance. However, it may print with poor ink absorption, causing the ink to run off the film, dirtying the printer and also your hands and clothes.

* Poorly ink-absorbent DTF film will cause ink bleeding.

High ink carrying capacity. Ink flow does not occur even when printing at high pass.

Fine lines and colors. Ink prints on without smudging and prints very fine lines.

Clean shaking powder. No excess DTF powder adheres to unprinted areas after dithering, ensuring that prints have smooth edges.

Easy to peel off. The DTF film is coated with a release layer, which is stable and uniform to ensure that the backing film will peel off smoothly and without sticking.

In the sample test, we can check the ink carrying capacity of DTF film by setting the pass number to the highest. DTF films with a poor-quality ink-absorbent or water-absorbent layer may bleed ink, color, or water during printing.

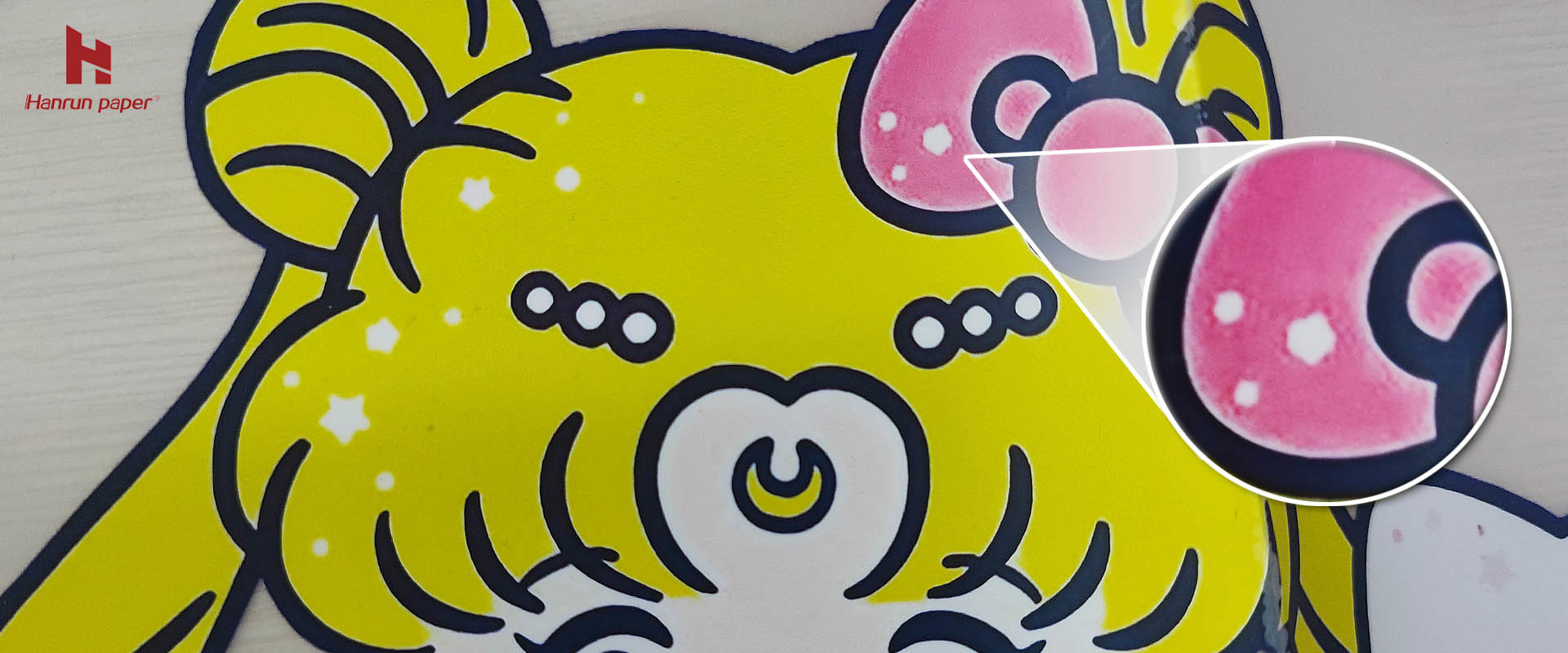

Printing fineness is a very important point in DTF quality inspection. It can reflect whether the coating of the film is uniform or not. In most cases, we choose some color blocks or fine lines for testing. In addition, we also suggest that you can add some gradient color test patterns.

*Noise may appear on the printed pattern if the coating of DTF film is not uniform.

Some samples will have residual powder on the edge of the pattern after shaking powder, which will leave a trace of hot melt glue on the edge of your transferred pattern and affect the aesthetics. The edge of the printed pattern of the film with a good powder shaking effect is clean and without residue.

*Comparison of shaking powder with and without residue.

Qualified DTF films are easy to peel off after pressing. Bad DTF films are difficult to tear off or damage the pattern. Especially for DTF films called "hot-peel", the requirements for the release layer are even higher. Hanrun Paper's 100μ hot peel DTF film has a high quality raw materials in the release layer that makes it easy to tear, allowing it to be peeled off instantly after pressing and ensuring the stability and uniformity of the print quality.

Hanrun Paper has been investing in the research and development of DTF digital printing technology since 2020 has always insisted on quality and innovation, and has obtained a patent for the invention of DTF film (Patent No. ZL202110519575.4). All DTF film series products are selected with full consideration of environmental protection factors and comply with OEKO standards.

If you still can't judge, welcome to send samples to us, and Hanrun Paper technical experts will help you test them for free and give you a reasonable purchasing suggestion. If you have any questions, feel free to contact us.

Choose sublimation paper? Focus on quality over price

Choose sublimation paper? Focus on quality over price

7 Factors To Consider Before Choosing A Digital Textile Printer

7 Factors To Consider Before Choosing A Digital Textile Printer

2024 Apparel Decoration Industry Trends

2024 Apparel Decoration Industry Trends

What are the features of digital textile printing equipment

What are the features of digital textile printing equipment